Back in late September the wife ordered me to make one final cut of the rear lawn before autumn kicked in. Actually, she'd asked me to do it several times over the dying summer weeks but I had managed to blot out her nagging and continue instead with my Platstation 'work' (those zombies ain't gonna shoot themselves y'know). Eventually however I reached an impasse where no further sex would be possible until I bally well did as I was told so I dutifully dusted the spiders off my faithful old Qualcast Quadtrak 30 that was stored in the garden shed, and got busy with the trimming despite the fact the lawn was pretty heavily overgrown by this point and was also wetter than my fish's tits.

After a few minutes of trying to chew through the thick wet grass, smoke started billowing out of the motor housing accompanied by the burning smell of electric death that signalled an end to my half-arsed green fingered tomfoolery and the start to yet another exciting repair project!

Despite being over ten years old and therefore argueably more economically viable to buy a new mower, I figured I'd change out the dead motor rather than scrapping the whole caboodle. A new motor and knife would be £64.20 (delivered inc. VAT) from www.mmtc.co.uk which comes in slightly cheaper than the cost of an eqivalent replacement mower and saves me both a trip to Argos to buy new and to the refuse centre to dispose of old. I figure a new motor and knife will get me another ten years out of the thing so long as I'm not stupid enough to try mowing down half a rain forest while hungover again.

Besides, I changed out the belt a couple of years ago after the old one snapped so hopefully today's repair will leave me with something pretty much as good as new mechanically.

If you're following any of these repair steps, obviously make sure the first thing you do is unplug it from the mains. You may also want to check you can disassemble the thing before ordering parts because y' don't want to splash out on expensive items such as a new motor only to find you can't get the old one out because of corroded screws or something!

Step 1. Remove the two screws on the green upper housing.

Step 2. Lift away the housing to expose the top of the motor.

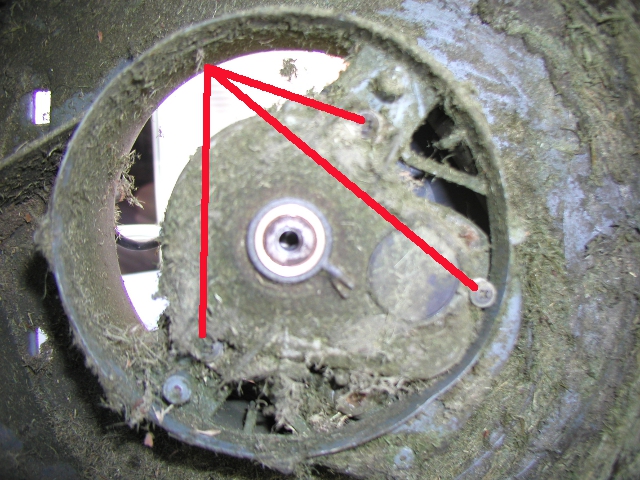

Step 3. Remove the bolt that holds the knife in place. My knife is pretty blunt so I'll be fitting a new one.

Step 4. Undo the three screws that hold the gearbox housing in place.

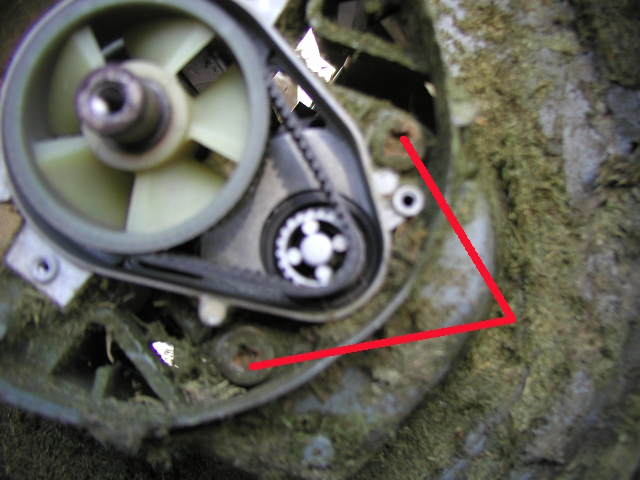

Step 5. Lift off the gearbox housing. If you have a mower with a whirring motor but a stationary knife, it's probably the belt you need to change and here's where you find it. A replacement belt is about fifteen quid.

Step 6. Undo the two large screws. This will loosen the motor enabling removal/refitting of the belt more easily.

Step 7. With the motor loose, the driveshaft and belt can be pulled away.

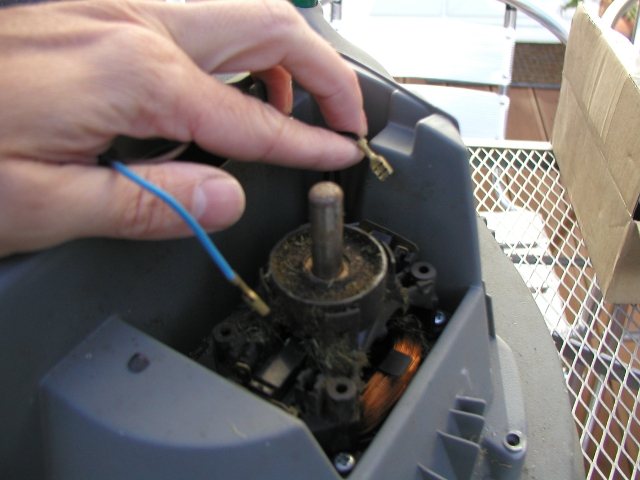

Step 8. Disconnect the wiring to the motor.

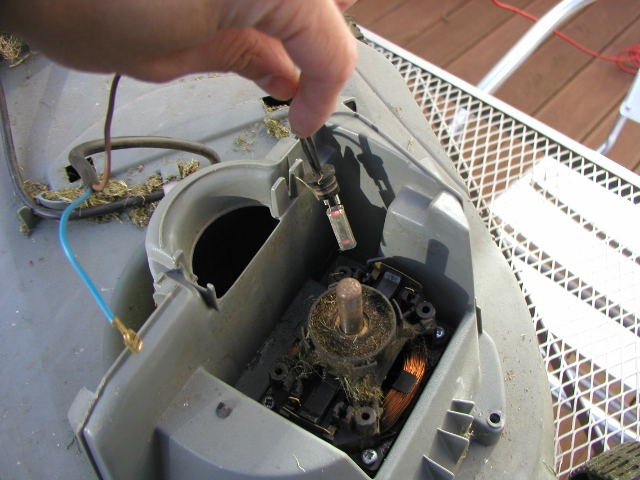

Step 9. Pull out the thermoswitch.

Step 10. Prise up the motor housing....

Step 11. ...and lift the housing clear.

Step 12. Lift out the old motor.

Step 13. If the new motor doesn't have the retaining nuts, remove them from the old one for re-use.

Reverse the steps to reassemble. When putting the gearbox back together, ensure it is clear of debris inside. Make sure you tighten everything as you don't want the knife flying off and removing your ankles the first time you use it. Also, be sure to put the knife on the right way around so the blade edge is moving forward.

Unfortunately now that winter is kicking in, full testing of my repairs will have to wait until the spring.

It's a damn shame.

:)